First door: The construction. Or: Happy birthday, O2!

Pubblicato: 01.12.2019

Iscriviti alla Newsletter

We begin with a special, but detailed topic (don't get used to it, today is only Sunday and we have time ;)). The reason for this is that Simon's friend Otto (pronounced "O-Two"), a civil engineer and future managing director of a Bissingen construction empire, is celebrating his birthday today. Therefore, best wishes from both of us and enjoy reading! :)

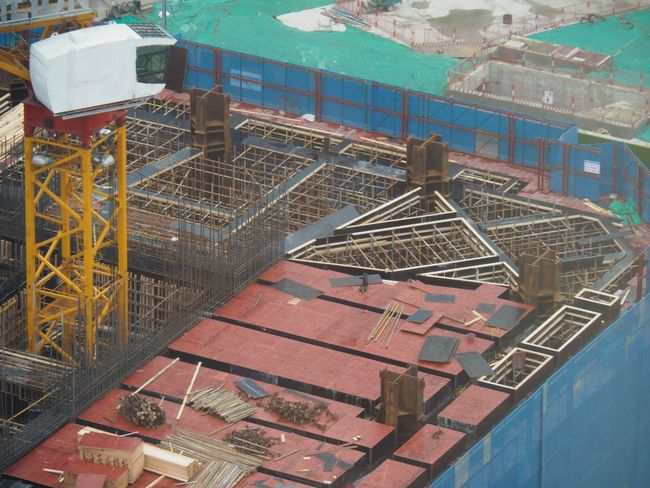

Already during the pre-assignment trip in July, we noticed a large construction site in front of the apartment. With an excellent view from the bedroom, we can observe how a 50mx50m high-rise building is being built here. What sounds sluggish looks like a real ant farm when you see it: Every day after work, the new floor looks different, there's hustle and bustle everywhere, and you can track every construction step piece by piece. Hours have already been spent observing.

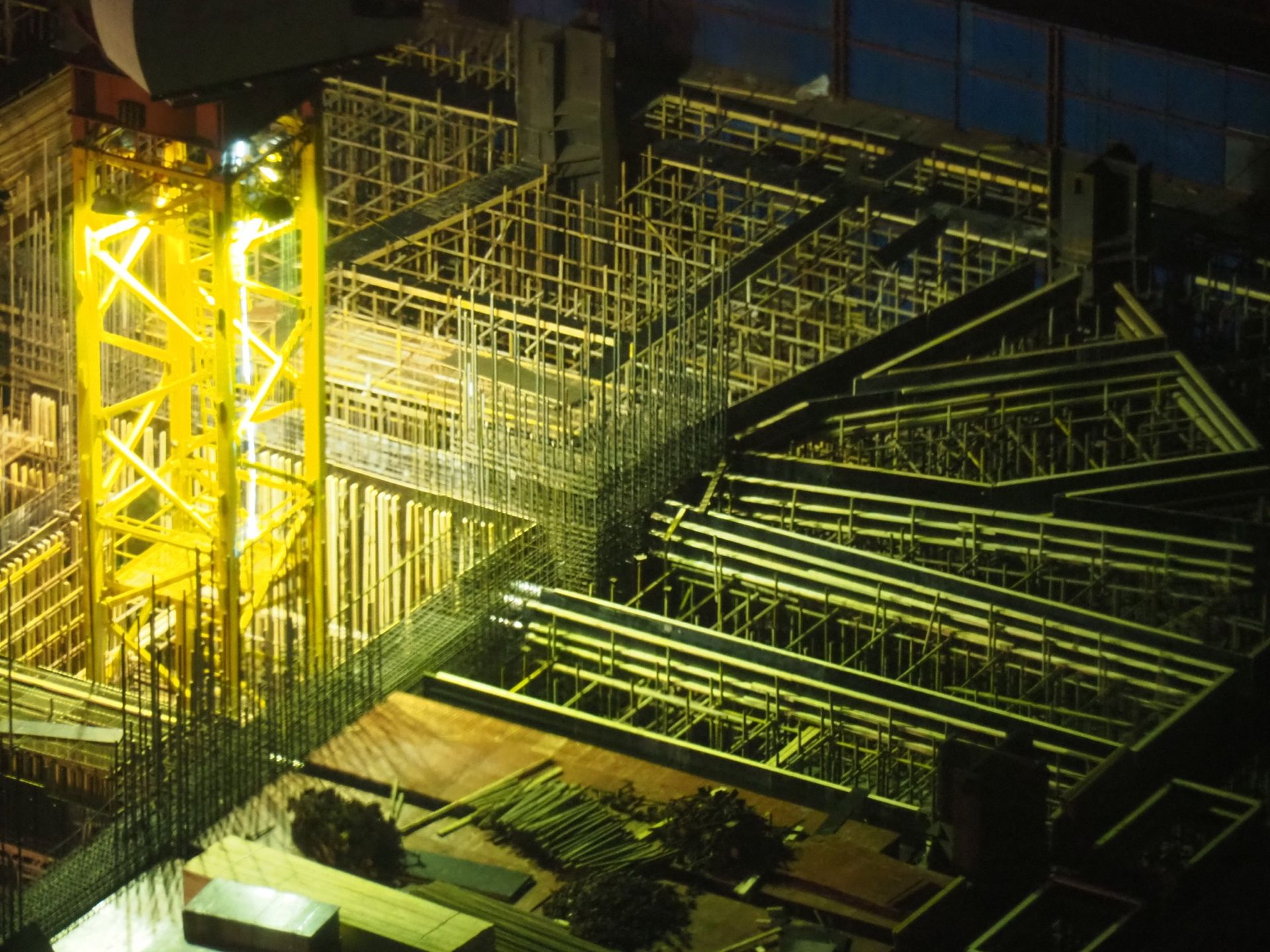

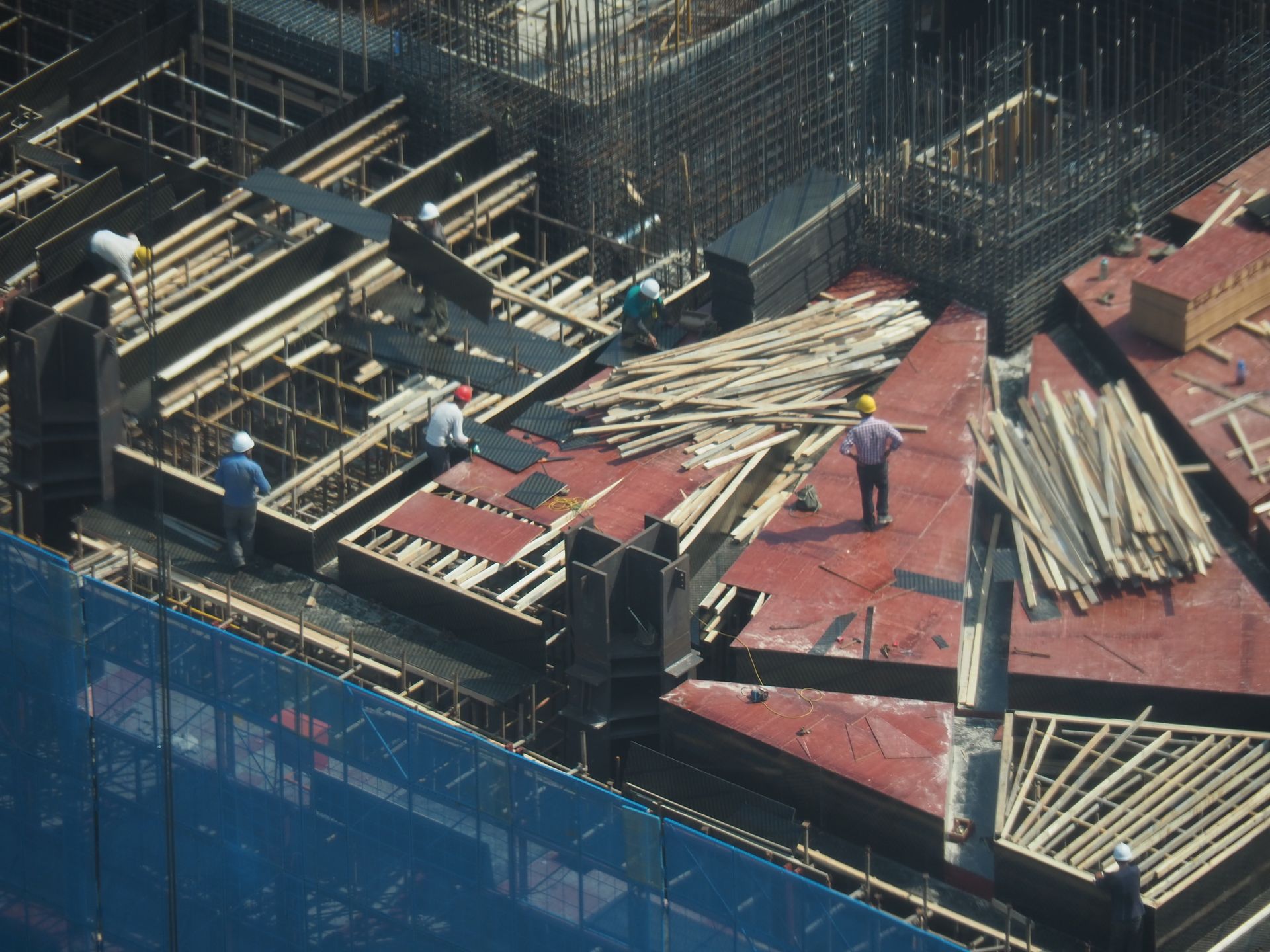

Each floor is manually formwork and cast, no prefabricated elements or precast ceiling elements that I have known so far are used. Instead, the entire lower floor is built with a work of art consisting of supports, on which the negative of the future ceiling is constructed with formwork panels. These already include the elevator shafts, staircases, and the supporting beams. The entire formwork template is then laid out with reinforcement. Specially shaped elements are pre-bent by 2 people in the yard, thousands of circles, angles, and rectangles, day in, day out.

Then comes the most disturbing process for us: pouring. The concrete is pumped up from the ground using two concrete pumps and distributed across the floor using a crane apparatus. This is how both halves of the floor are poured one after the other. Concrete trucks arrive every 5 minutes. This process takes about 15 hours per half and always takes place overnight. The loud pumping of the two trucks hits our bedroom ... perfect. After hardening, the blue safety fence is moved up one floor in segments, and the entire process starts again.

The entire process for one floor takes about a week and consumes roughly 1500 tons of concrete and 100 tons of steel. For this, 50 men are employed on the top floor and 50 in the yard, working in 12-hour shifts, 7 days a week, in all weather conditions. What is happening in parallel in the construction of the underground garage and the intermediate floors is hidden from our curious eyes.

The workers generally give the impression of being poor. Many go home in the evening with rusty bicycles or ten people on the 3-wheeled electric bier. Only a few have an e-scooter that is seen everywhere. We suspect that most of them are migrant workers from rural China who earn money here to send home.

Iscriviti alla Newsletter

Risposta