Walnut Harvest

Publicat: 05.05.2019

Aboneaza-te la Newsletter

From Huonville we drive up the east coast to Swansea, a small village right on the coast. We heard about a walnut farm where we would like to work. In a few hours, we found the farm and spoke with the manager. He cannot guarantee us a job but allows us to camp on his property. After a week of waiting, the harvest begins.

We are a relatively small group compared to other companies, probably because most of the work is done by machines.

About twenty Australian men work for the company all year round. Only during the harvest season are backpackers needed to collect the walnuts. This year, there are about fifteen backpackers - all French except for one other woman from Belgium, from the Dutch-speaking part.

The first two days, we are guided through all the safety regulations and the employment contract. A lot of paperwork needs to be signed, we need to prove that we can drive a car, and the different machines are explained to us. Then finally, we get started:

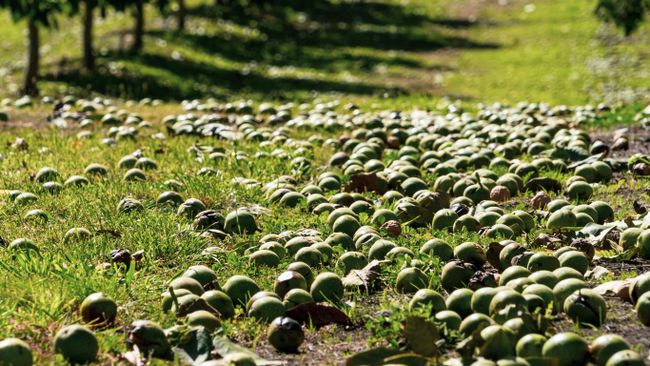

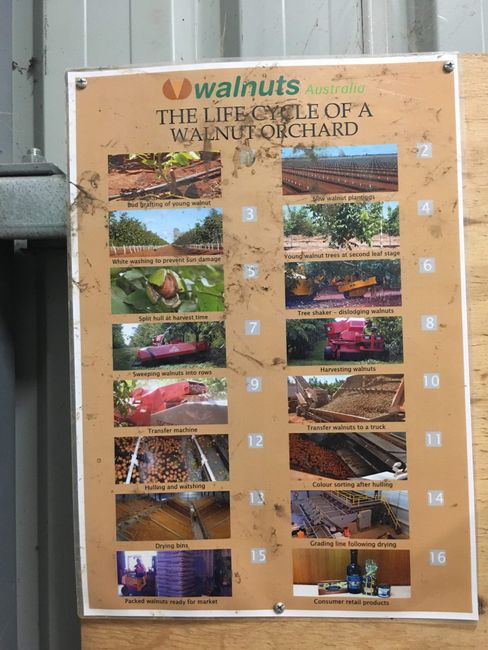

First, come the so-called 'shakers', as the name suggests, this machine is used to shake the walnut trees. On the right side, it has an arm that can grab the tree and shake it vigorously, causing the walnuts to fall to the ground.

The next step is done by the 'sweepers'. Flo got to drive a sweeper alongside all the Australian workers. The sweepers blow the walnuts with a large fan into the center, between the two rows of trees. Sometimes Flo has to drive along the same row three or four times to leave a straight line of nuts in the center. Flo is doing a good job. Everyone is very satisfied with him, and our manager offers him to come back for the next season.

Then come the 'rakers', they all have a rake and walk through the rows of trees to rake nuts that the sweeper missed into the center and remove larger branches and stones. That was the work of most backpackers. They repeatedly say that the work is very difficult; they have to crawl under the trees all day and sometimes search for walnuts in very tall grass.

Then finally, the nuts are ready to be harvested by the 'harvester'. Another machine that drives through all the rows and sucks up the nuts and transports everything to its trailer. From there, the walnuts go into shipping containers.

The containers are brought to the hulling line by trucks. The hulling line is a small factory where all the stones and some branches are separated from the nuts. It operates 24 hours, seven days a week. There is a team during the day and a night shift, from 6 am to 6 pm or from 6 pm to 6 am. I got to work night shifts.

The container, full of nuts, stones, branches, and whatever else is found, is loaded onto the tipper and then slowly tipped into the hopper. The hopper transports the walnuts on a conveyor belt into the building. Next, the nuts are sieved through a metal screen to filter out larger sticks and branches. Then they are filtered through the rock tank. The rock tank is a large tank filled with water; the stones sink to the bottom, and only the nuts are directed to the inspection table. There, a person, sometimes two, collects all the sticks. The table is quite large and has the wrong height to make work comfortable.

Next, the nuts are rinsed with chlorine water and then dried again by four hoses. Then, using the SwiftLift (a movable arm that we can drive in and out of the containers), the walnuts are transported back into a container, which this time has a fan installed, and brought to New South Wales (Australian state) as soon as possible.

Our task at night is to prepare the containers and, of course, collect the sticks. Another position is at the waste belt, a conveyor belt where all the trash, stones, sticks, and bones are transported into a truck. Heavy walnuts that sunk in the rock tank occasionally come out there; they have to be removed because they must not end up in the trash. A walnut is worth AU$0.60, which can add up quite a bit if one nut comes out every minute.

I enjoy working at night; it is certainly an interesting experience even though Flo and I hardly see each other. I thought it would be more difficult for me to switch from day to night, but it works quite well, and we have fun together at night. We are a small team consisting of five people. We quickly become a well-coordinated team, although we never handle as many containers as the day shift, we still do a good job.

It feels good to work for the Webster company. Webster makes us feel important, and when we work at night or on weekends, we are better compensated for it. In my opinion, our manager is doing a good job, and it is nice to be able to perceive this difference. (A difference like day and night, ha ha!)

Aboneaza-te la Newsletter

Răspuns

Rapoarte de călătorie Australia