What exactly are we learning here?

Публикувано: 29.09.2019

Абонирайте се за бюлетин

Some of you will surely wonder what exactly we are learning here. Therefore, I will try to explain all the study contents and subjects here and give my personal opinion on the subjects.

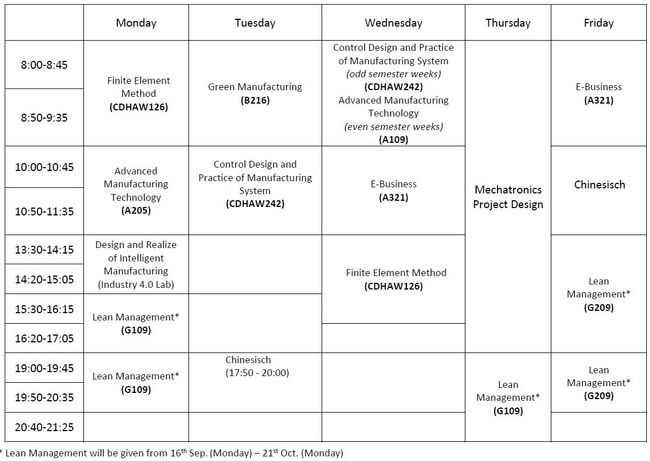

You can see all the subjects on the timetable. However, the times are not quite correct, as Lean Management in particular is compressed.

But now let's talk about the subjects:

1. FEM (Finite Element Method)

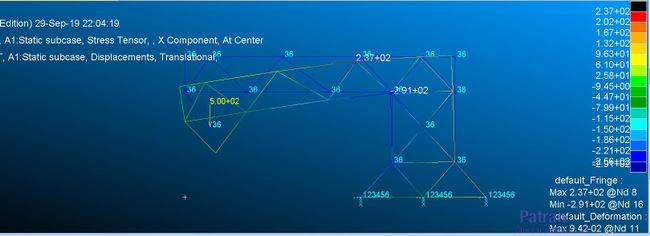

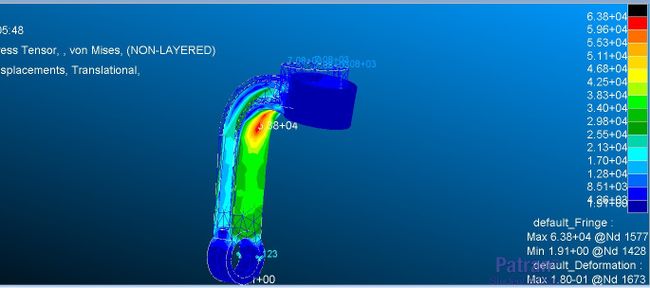

In FEM, the goal is to find a way to mathematically describe complex real systems in order to perform simulations and calculations. For this purpose, the object is divided into many simple geometric elements (hence the name). These can be mathematically described more easily, and from many individual elements, an approximation for the overall object can be created. We always have a theoretical unit on Monday, which deals with the mathematical basics and methods, and a practical unit on Wednesday, where we practice simulations and work with Nastran/Patran (simulation software).

I find the subject very interesting in itself, and it builds on many contents we have already covered while also teaching us new things. However, the practical units are simply clicking through according to instructions without much explanation, and the lecture is somewhat difficult to understand because the professor's English is not very good (but I don't blame him for that, as we have a certain basic knowledge and understand what he means)

Unfortunately, neither the professor nor the assistant can help us much when problems arise during the simulation. Sometimes they just say, 'That's because of the software. Do it again at home.' That is not necessarily the purpose of studying, but unfortunately, it happens from time to time. So it's always a hope whether it works today or not.

2. AMT (Advanced Manufacturing Technologies)

As the name suggests, it's about production technologies. So far, we have covered the following main topics:

- CAD/CAM, NC, FMS, CIM, and technologies for RP&M.

For each of these topics, we are presented with definitions, advantages and disadvantages, and sub-areas.

However, the subject is not that exciting. The lecturer just reads from her script, and most of us do their homework during the lectures because there is no need to take notes or think. Even for me in the second row, it is almost acoustically incomprehensible what she is talking about. Moreover, the presentation is from about 15 years ago, because when it comes to using floppy disks for storage together with CAD programs, it is simply not up to date anymore. It even mentioned Gopher. I have never heard of that before, and apparently, nobody has been using this service since the early 2000s... At least the topics in the upcoming presentations are more current, such as 3D printing.

So the subject is very mixed, even though some of the topics are interesting, they are just not presented very well.

3. Design and Realize of Intelligent Manufacturing

In this subject, we deal with manufacturing processes and especially with the examination and analysis of their processes. There is also a practical unit that deals with working with PLCs (Programmable Logic Controllers).

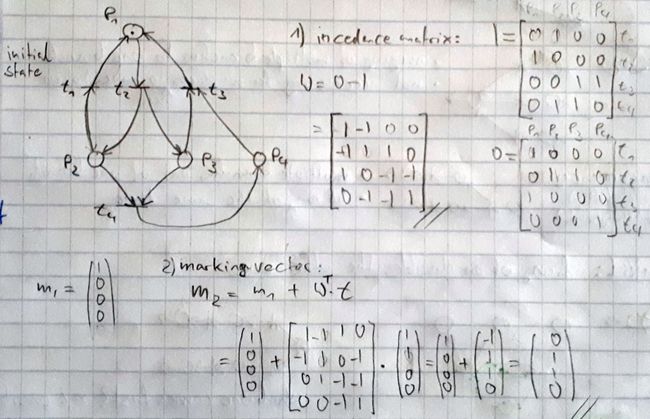

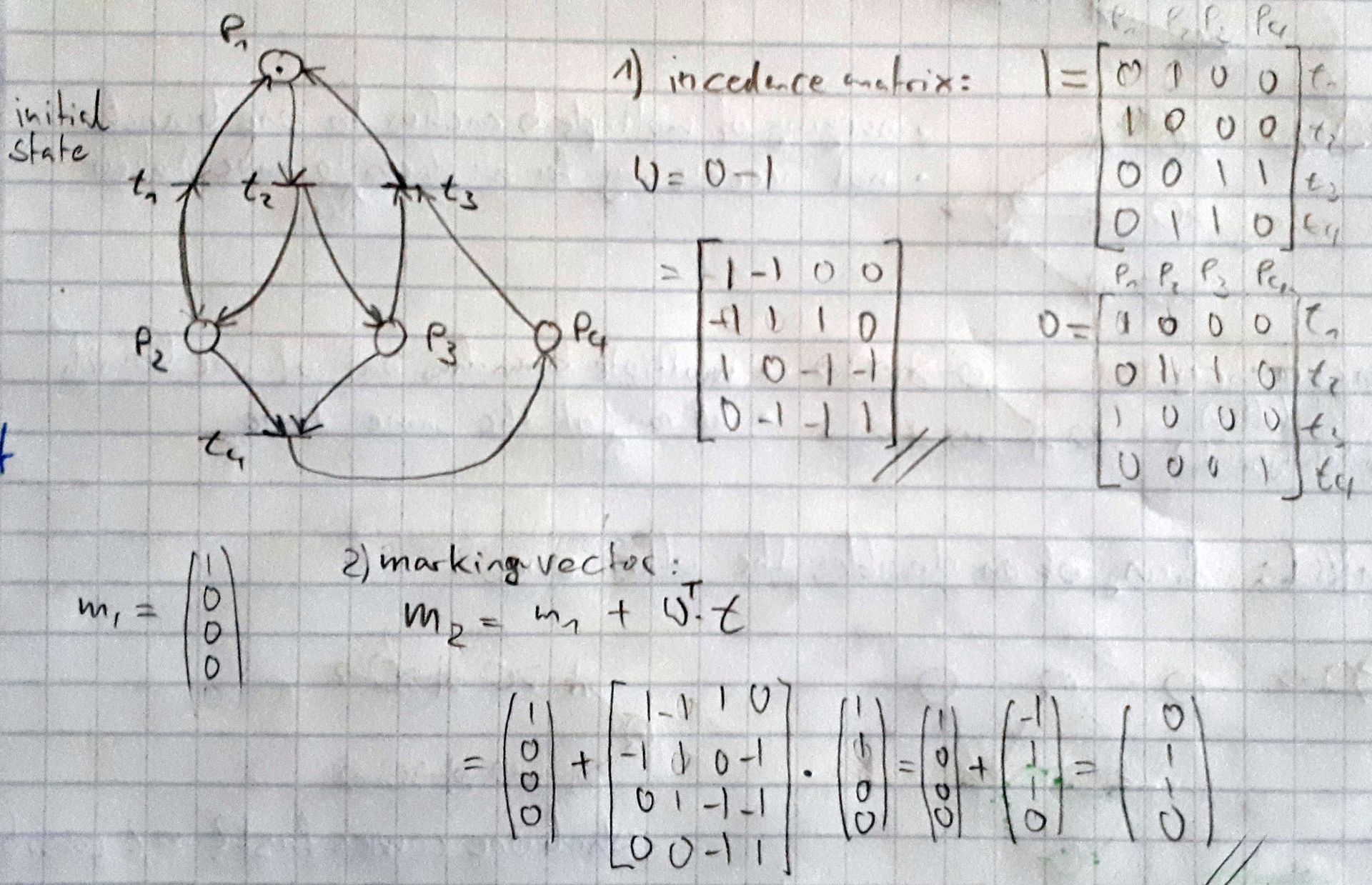

Currently, we are mainly dealing with Petri nets. These are a way to represent the sequence of steps in a process and the dependencies between them. By using some math, various states of the system can be calculated, and it can be determined whether deadlocks can occur. These are situations where the system blocks itself and cannot continue to run.

The subject is taught by the head of the Mechatronics department, and she does it quite well. You have to pay attention, or you quickly lose track of where she is. Fortunately, most of the content is taken directly from a book, so many things can be easily reviewed.

However, all of this is not easy to understand, and it took me a while to grasp it, but now I understand it quite well. At least the lecturer is aware of this, as apparently previous cohorts had great difficulty understanding all of this. We will also have a midterm exam next week because she wants to test our knowledge.

I find it an interesting subject because it is an extension of the control technology we have already learned at EAH.

4. E-Business/E-Commerce

As the name suggests, it is about everything related to online businesses. We are shown methods for market and customer analysis, and the professor provides many examples. He also talks a lot about the differences between China, Europe, and the USA, which I personally find very interesting. It gives us a good insight into the cultural differences and how advanced China is compared to Germany, for example.

The units are fun because he often engages in discussions with us and lightens up the atmosphere. From my point of view, it is one of the better lectures here.

5. Green Manufacturing

Again, the name says it all. We cover everything there is to know about sustainable production. This includes closed-loop production systems, clean energy, and environmentally friendly manufacturing, packaging, and transportation.

The lecturer speaks good English and does a good job, even though it is again just frontal teaching. She incorporates many examples to make her points clearer.

In this subject, we have to write a term paper and also give a presentation. Sophie, Selina, and I are working together on a presentation that focuses on the system of zero-waste or unpackaged stores.

6. Lean Management

LM is the only subject that is taught in German. The professor is only here for one month, so we have to cover many lectures in a short time. 3-4 hours at a stretch are incredibly exhausting, and we have shortened the breaks so that we don't have lectures until late in the evening. Nevertheless, the lectures still go on until 7 or 8 pm. It is very difficult and exhausting to concentrate for such a long time. (You can see the times on the timetable)

In addition, the content is quite boring, at least from my point of view. Actually, the subject is intended for WI, but basically, everybody is included. It deals with management and business administration. The basic idea of Lean Management is roughly: 'Continuously searching for the better of tomorrow within the given of today.' So, we are shown different ways to find and fix management errors. In addition, there is an economic analysis of companies and projects through calculations of profitability and efficiency and all that nonsense.

Of course, it is good to have heard about all of this, but I already didn't like it in business administration, and it hasn't changed. I find it incredibly boring and dry. It is less about understanding and more about memorization. Sometimes, the professor contradicted himself, and just the fact that it doesn't matter to him how we round numbers or whether all units are always correct contradicts pretty much everything we have learned in our studies so far.

At least we have an exam on Friday, and then life will be much easier, and we will have much more time for everything else.

7. Chinese

Thomas and I decided to take a Chinese course here again. We have already reached A1.1 level in Germany, but that is by no means enough to get by here. Sophie is not participating due to time constraints.

We have 2 units of about two hours each per week. Tuesday evening and Friday morning. With a different teacher each time. Both are doing very well, and it is different to learn from a native speaker. We basically started from scratch again, which was not a problem because it provided a review. The focus is mainly on speaking, and we mostly work with Pinyin, which is the transcription using our letters. Writing and characters are in the background for now and are mostly done as extra work. Overall, it is a lot of fun, and I can see that I am making progress, although I certainly can and need to do more.

8. Intelligent Manufacturing

1. Creating a web interface with Python for control and access to data on the server.

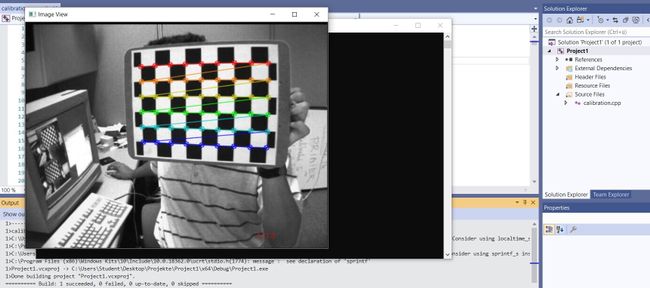

2. Object recognition using a camera. This way, we know where the workpiece is located at any given moment. For image processing, we use Visual Studio with OpenCV.

3. Setting up communication between machines and sensors using OPC.

4. Creating a digital twin of the overall system. This means creating a virtual representation of reality that shows us the current state of the system.

The units are taught by two lab assistants, whose English is quite alright, and one of them even speaks German.

From my point of view, this is the most interesting subject because it is about applying individual knowledge to an entire system.

However, it is currently not very well presented. The lab assistants go through many things very quickly without explaining much. This means that we often can't keep up and have to do a lot of additional work. In addition, programming skills are sometimes required that none of us have, and some of our classmates just sit around and can do little/nothing because their laptops are not powerful enough for the software. (We work with a virtual machine, which requires a certain basic performance)

So there is still room for improvement, but when I understand something, it is really fun because I am actually learning something here. Let's see how well we manage to write the reports and how well the oral test goes.

9. Mechatronics Project

Thursday is basically dedicated to the project. There were various topics, and everyone could more or less freely choose one. I am in a group with Thomas, Réne, Matthias, and Zhang. We are currently working on designing a smart snow removal system for roofs. We have a free hand and take care of everything ourselves. We are trying to carry out the whole project according to a DIN standard, which has worked quite well so far. We have decided on a system that checks the roof for snow and then removes it using a salt solution. We are building a prototype with a light barrier, photodiodes, water sensors, and the corresponding pumping system. Everything is controlled by an Arduino. We have to program everything ourselves, assemble it, and also do a simulation. So there is a lot to do, but we are making good progress.

Maybe Sophie will find the time to write about her project as well, but currently, LM is more important, and we will take care of it afterwards...

Written by: Friedemann

Абонирайте се за бюлетин

Отговор (1)

Ulf

Nǐ hǎo Friedi,

Omi und ich waren vergangene Woche in Freiberg, wo uns 6 noch lebenden Absolventen unserer Fachrichtung von der TU anlässlich des 60jährigen Jubiläums unseres Diplom im Jahre 1969 eine "Goldene Diplom-Urkunde" in einer Feierstunde überreicht wurde. An diesen Tagen haben wir viel übere unser Studium damals und die Studentenzeit in Freiberg gesprochen! Daher war es sehr interessant Deinen Bericht zu lesen. Ich habe den Eindruck, dass Du eine gute Einstellung zu den Studienfächern hast - schön und sicherlich auch für später ist, dass Du dir noch das Chinesisch aufgebürdet hast.

Viel Erfolg für die bevorstehenden Tests, Reports und/oder Prüfungen wünschen Dir Opi und natürlich auch Omi